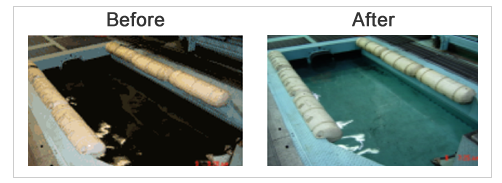

PROBLEM: A watercraft manufacturer had a problem with the test tank water getting so contaminated that they had to wash down the hull after each test run. The test tank was laden with carbon, oils, dirt, and hydrocarbons from the test and manufacturing process. The problem was unique in that 98% of the particles were smaller than 5 microns.

SOLUTION: After analysis and research, JDI, Inc. recommended that a filtration system continuously filter the water. After installation of the purification system, the hulls are clean and water quality greatly improved.

The test tank visibility was such that the floor of the test tank could easily be seen and they no longer need a full time employee to clean each and every hull.

Because of your separators and service, I was able to help one of my customers in a pinch and I have been able to grow my business from 3 employees to 26!‚ÄĚ

-Gabe, Portland, OR

Case Studies - Heavy Equipment

Read our case studies to see how JDI, Inc.ís equipment and services have solved a multitude of complex filtration issues.

Case Study: Bubble Test Tank

Read our case studies to see how JDI, Inc.ís equipment and services have solved a multitude of complex filtration issues.

Cutting Oil

A manufacturing facility producing specialty metal machined products contacted us to help them recycle the oil they used in their screw machines.