For over 30 years, our engineers have been helping our clients improve their processes and oil maintenance programs to achieve the following goals:

- Improved reliability, performance and safety of their equipment.

- Reduced maintenance and fluid expenses.

- Elimination of root causes of oil and equipment failures.

Our experience and expertise will help you develop oil maintenance programs that are cost effective, integrated and proactive. Depending on your application, we can provide a range of services, including:

- Fluid Sampling

- Oil Analysis reporting

- Equipment Condition Monitoring

- Comprehensive Historical Trend Reporting

- Equipment & Process Recommendations

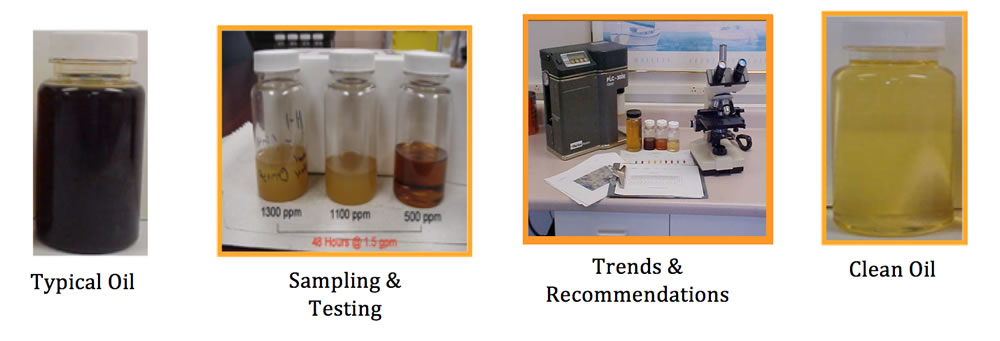

As part of any program, we do an initial baseline and testing study that acts as the foundation for subsequent analyses. It includes the collection of plant equipment data, fluid data, and maintenance procedures.

After analyzing the initial data, we can help you determine the overall chemical condition of your oil and potential machine maintenance issues. If needed, we can also recommend corrective action, including additional filtration or replacement products.

Then, on a quarterly or annual basis, we will do comparable testing to update the baseline and evaluate the maintenance program effectiveness. We will review the data with you and provide a summary for each sample that can be used to modify the current methods or trigger immediate corrective action.

We have found that by implementing a structured oil monitoring and maintenance program, machine contamination and downtime can be greatly reduced, resulting in a very fast payback!

What is Oil Depth Filtration?

Depth Filtration is one of the most efficient methods of filtration since the fluid is filtered throughout the axial length of the media rather than just on the surface of the media. The integrity of the filter element is maintained even as it loads up with contamination and the delta-P (pressure across the filter) goes up.

The hydraulic pressure of the fluid compresses the layers of media together and prevents a channel from forming that could allow unfiltered fluid to pass through the element. There are several numerous advantages over standard filters including:

Dirt-Holding Capacity - In typical oil filtration applications, depth filter elements have dirt-holding capacities of several pounds.

Water Absorbency - Depth filters have excellent water absorption qualities; in many applications, they can absorb enough water to keep water contamination in oil to 30 ppm or below.

Beta Ratio - Filtration beta ratios are a measure of the filtration efficiency for particles of all different sizes.

Beta ratios are standardized, allowing you to compare filtration performance from one filter to another. However, when using beta ratios to compare filter performance, you must take into consideration the differences between standard filters and depth filters. Standard filters often have high beta ratios; however, they quickly load with contaminant, causing a spike in differential pressure which leads to short element life. On the other hand, depth filters have both high beta ratios and larger dirt holding capacities, which allows for continued performance over a longer period.

Flow Rate - The recommended flow rate will vary based on the viscosity, temperature, and cleanliness level of the fluid being filtered. In most applications, a slower rather than faster rate yields the best results. Selecting a combination of filters and flow rates to yield startup-pressures in the 15-30 psi range will result in maximum filter life.

What is the life of the filter elements? - The answer to this question is: it depends, on a bunch of stuff!

Is the oil new? Has the new oil been pre-filtered? New oil is dirty oil, and if you have a high purity application, all new oil should be filtered prior to being added to the system.

If the oil in the system is dirty, the life of the elements will depend on how contaminated the oil is to start off with and how clean you need the oil to be. If a filtration system is installed when the oil is full of contaminants, you may have to change the filters more frequently at the beginning of the process. Once the filtration system removes the majority of the contaminants and your oil becomes cleaner, the length of time between filter changes will increase.

How long will my oil last with filtration? - It depends on the process, the type of contamination as well as the level of contaminants and the desired quality of the oil. With filtration, our goal is to filter the oil for as long as possible to extend the life while reduce oil disposal costs. In some applications, the oil’s life can be extended to years. It depends not only on the contamination levels, but also on the additive packages.

For those applications that rely on precision and high reliability, we recommend our clients institute a systematic fluid management system including testing their fluid on a regular basis so that they maximize fluid life, equipment reliability, and operating efficiency.

Dedicated Oil Filtration Systems

Dedicated Oil Filtration Systems Portable Oil Filter Carts & Dedicated Oil Filtration Systems

Portable Oil Filter Carts & Dedicated Oil Filtration Systems Engineered Depth Filters

Engineered Depth Filters